Sealing Technology: Understanding Hermetic Feedthroughs

In the world of technology, hermetic feedthroughs play a crucial role in ensuring the safe and reliable operation of electronic devices. These specialized components are essential for creating a seal that prevents the leakage of gases or fluids from one side of a barrier to another. Understanding how hermetic feedthroughs work and the various technologies used in their construction is key to maximizing their effectiveness in different applications.

What are Hermetic Feedthroughs?

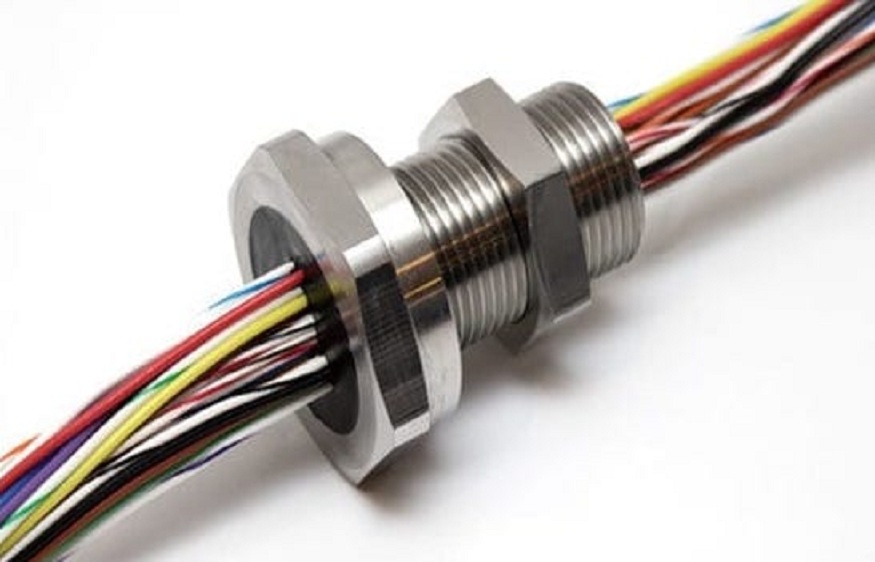

Hermetic feedthroughs are a type of sealing technology used to pass electrical signals, power, or fluids through a barrier while maintaining a hermetic (air-tight) seal. These components are commonly found in a wide range of industries, including aerospace, medical devices, and industrial equipment. The primary function of hermetic feedthroughs is to prevent the ingress of contaminants and the egress of critical substances, ensuring the integrity of the system they are installed in.

How do Hermetic Feedthroughs Work?

Hermetic feedthroughs are typically made up of a conductive material, such as stainless steel, that is sealed within a ceramic or glass insulator. The feedthrough is then welded or brazed to the barrier, creating a strong and durable connection. This design allows for the transmission of electrical signals or power while maintaining a complete seal, even under harsh environmental conditions. The key to the success of hermetic feedthrough lies in the quality of the seal and the materials used in their construction.

Types of Hermetic Feedthroughs

There are several different types of hermetic feedthroughs available, each designed for specific applications and requirements. Some common types include:

- Glass-to-metal seal feedthroughs: These feedthroughs use a glass insulator sealed to a metal conductor, providing excellent electrical insulation and hermetic sealing.

- Ceramic feedthroughs: These feedthroughs use a ceramic insulator, which is highly resistant to temperature and chemical corrosion, making them ideal for harsh environments.

- Multi-pin feedthroughs: These feedthroughs feature multiple pins or conductors sealed within a single insulator, allowing for the transmission of multiple signals or power sources.

Applications of Hermetic Feedthroughs

Hermetic feedthroughs are used in a wide range of applications, including:

- Medical devices: Hermetic feedthroughs are essential for implantable devices, such as pacemakers and neurostimulators, where a reliable seal is crucial for patient safety.

- Aerospace: Hermetic feedthroughs are used in aircraft systems to ensure the reliable transmission of electrical signals and power in high-altitude and high-vibration environments.

- Industrial equipment: Hermetic feedthroughs are used in various industrial processes, such as vacuum systems and semiconductor manufacturing, where a leak-tight seal is critical for operation.

Choosing the Right Hermetic Feedthroughs

When selecting hermetic feedthroughs for a specific application, several factors should be considered, including:

- Operating conditions: The temperature, pressure, and environmental conditions the feedthrough will be exposed to.

- Sealing method: The type of sealing technology used in the feedthrough, such as glass-to-metal or ceramic.

- Number of conductors: The number of signals or power sources that need to pass through the feedthrough.

By understanding these factors and working with experienced manufacturers, such as Hermetic Solutions Group, companies can ensure they choose the right hermetic feedthroughs for their needs.

Conclusion

Hermetic feedthroughs are an essential component of modern technology, providing a reliable seal for the transmission of electrical signals, power, and fluids. By understanding the different types of hermetic feedthroughs available, their applications, and how to choose the right one for a specific use case, companies can ensure the integrity and reliability of their systems. Working with experienced manufacturers and suppliers is key to maximizing the benefits of hermetic feedthroughs in various industries.